The retail world moves fast, and your in-store experience needs to keep up. But how do you test bold new ideas for store layouts or displays without the risk of a full-scale investment? This is where rapid prototyping shines. It allows you to turn concepts into tangible, physical models that your teams can actually see and touch. This simple step gets everyone from design to marketing aligned on a single vision. You can pivot confidently, refine your ideas, and create an environment that truly connects with shoppers—all before committing to a major rollout.

Key Takeaways

- Test your fixtures physically to avoid costly mistakes: Rapid prototyping allows you to hold a tangible model of your design, helping you identify potential flaws in function, aesthetics, or durability before you commit to a large-scale manufacturing run.

- Select the right method for each stage of development: Your prototyping needs change as your design evolves. Use faster, less expensive methods for early-stage concepts and more precise, high-fidelity methods to validate the final version before production.

- A clear strategy is the key to an efficient process: Define your goals, budget, and feedback loop before you begin. Knowing exactly what you need to learn from each prototype ensures you get valuable insights without wasting time or money on unnecessary iterations.

What Is Rapid Prototyping?

Before you commit to a full-scale production run of a new retail display or fixture, you need to know if the design actually works. Will it hold your products correctly? Does it fit the aesthetic of your store? This is where rapid prototyping comes in. It’s a game-changer for turning a great idea into a tangible, tested product without the high stakes of mass manufacturing. It allows you to see, touch, and test your concepts in the real world, ensuring the final product is exactly what you envisioned.

How It Shapes Your Product Development

So, what exactly is it? At its core, rapid prototyping is a collection of techniques used to quickly fabricate a physical model or part from a 3D computer-aided design (CAD) file. Think of it as a dress rehearsal for your product. The main goal is speed—creating a tangible model you can hold, test, and evaluate in a fraction of the time it would take with traditional methods. This allows your design and engineering teams to spot flaws, test ergonomics, and validate the overall concept before you invest heavily in tooling and production. It’s all about making smarter decisions, faster.

Where Does Prototyping Fit in Your Workflow?

Rapid prototyping isn’t just a single step; it’s a crucial part of an iterative design cycle. It bridges the gap between a digital concept and a physical product, allowing your team to test and refine designs in a practical way. Instead of discovering a critical design flaw during the first production run (a costly mistake), you can catch it early. By creating multiple versions of a prototype, you can address technical challenges and improve functionality throughout the development process. This hands-on approach gives you a much clearer understanding of how your final product will look, feel, and perform long before it hits the factory floor, ensuring the final result meets your exact specifications.

The History of Rapid Prototyping

Early Concepts and Layered Modeling

Rapid prototyping might seem like a recent invention, but its foundational ideas have been around for over a century. The core concept of building a three-dimensional object layer by layer has roots in 19th-century techniques like topography and photosculpture. These early methods were used to create layered maps and sculptures, establishing the basic principle of additive manufacturing long before the first 3D printer was ever imagined. This historical context is important because it shows that rapid prototyping isn't just a fleeting trend; it's the modern evolution of a long-standing desire to bring two-dimensional plans into the three-dimensional world, making it easier to visualize and refine complex designs.

The Birth of Stereolithography (SLA)

The real breakthrough came in the 1980s, transforming prototyping from a manual craft into a digital process. In 1986, Charles Hull patented a technology called stereolithography, or SLA, which is widely considered the first commercial 3D printing method. SLA works by using an ultraviolet laser to trace a design onto a vat of liquid photopolymer resin, hardening it layer by meticulous layer until a solid object emerges. This invention was revolutionary because it directly connected a digital CAD file to a physical part, creating a seamless path from screen to reality. It laid the groundwork for all modern 3D printing technologies and opened the door for designers and engineers to create complex, accurate models with unprecedented speed.

The Rise of Fused Deposition Modeling (FDM)

Just a few years after SLA made its debut, another key innovation arrived that would make rapid prototyping even more accessible. In 1988, Scott Crump developed Fused Deposition Modeling (FDM), a method that builds objects by extruding a thin filament of thermoplastic material through a heated nozzle, essentially drawing the object layer by layer. If you’ve ever seen a desktop 3D printer in action, it was likely using FDM technology. This approach was simpler and more cost-effective than SLA, which helped bring prototyping capabilities out of specialized labs and into more design studios and workshops. The development of FDM was a critical step in democratizing the technology, allowing more businesses to adopt an iterative design and prototyping process to perfect their products before manufacturing.

Why Use Rapid Prototyping?

So, why should you make rapid prototyping a non-negotiable part of your process? Think of it as a strategic shortcut. Instead of moving from a digital design straight to mass production—a move filled with risks and unknowns—prototyping gives you a crucial checkpoint. It’s your chance to hold a physical version of your idea, test its functionality, and see how it feels in a real-world setting before you commit to a full production run. This step is especially important when you’re developing custom retail fixtures or displays that will be rolled out across dozens or even hundreds of locations.

Bringing a tangible model to the table changes the conversation. It allows your team, stakeholders, and even customers to interact with the design in a way that a 2D drawing or 3D render simply can’t match. You can identify design flaws, confirm material choices, and refine the user experience early on. Ultimately, rapid prototyping helps you move forward with confidence, knowing that your final product is not only well-designed but also practical, manufacturable, and aligned with your brand’s goals. It’s about making smarter decisions faster, saving money, and creating a better end product.

Go from Idea to Product Faster

One of the most significant advantages of rapid prototyping is how it accelerates your entire project timeline. Instead of waiting weeks or months for a traditional prototype, you can have a functional model in your hands in a matter of days. This speed allows your team to quickly iterate on designs. You can test multiple concepts in the time it would have taken to produce a single traditional model. For a retail rollout with tight deadlines, this is a game-changer. Faster iteration means faster problem-solving, leading to quicker approvals and a shorter path to final production. This process helps get your new fixtures into stores on schedule, without compromising on design quality.

Test Your Ideas Without Breaking the Bank

Committing to thousands of units of a new store fixture without testing a physical model is a huge financial risk. Rapid prototyping allows you to validate your concept without the massive upfront investment in tooling and materials required for mass production. Creating a prototype is a low-cost way to confirm that the design is structurally sound, the materials are appropriate, and the fixture functions as intended. If you discover a flaw or an opportunity for improvement, you can make changes to the digital file and produce a new version quickly and affordably. This design, engineering, and prototyping phase is your financial safety net, preventing costly mistakes before they impact your bottom line.

Get Real Customer Feedback, Faster

A 3D render on a screen is one thing; a physical object you can touch and interact with is another. Prototypes allow you to gather meaningful, real-world feedback from key stakeholders—whether it’s your marketing team, store managers, or a customer focus group. People can see how a display presents merchandise, test its durability, and assess its overall impact within a retail environment. This hands-on feedback is invaluable for refining the design. Catching a potential issue, like a shelf that’s too high or a sign holder that’s easily knocked over, during the prototype stage saves you from making expensive changes after production has already started.

Avoid Costly Manufacturing Mistakes

A design that looks perfect on paper might present unexpected challenges during production. Rapid prototyping acts as a bridge between your design and the final manufacturing process, helping to identify potential issues early. By creating a physical model, you can test assembly methods, check for tight tolerances, and ensure all components fit together correctly. This step provides critical insights that inform the final domestic and international manufacturing strategy. It helps your production partners anticipate challenges and refine their processes, leading to a smoother, more efficient production run with fewer errors and delays. This proactive approach ensures your fixtures are not only well-designed but also built for seamless, large-scale production.

Types of Prototypes by Development Stage

Not all prototypes are created equal, and the type you need depends entirely on what you’re trying to learn. Think of it like this: you wouldn’t build a fully functional, store-ready display just to test whether a shelf is wide enough. The key is to match the prototype to your current stage in the development process. Prototypes generally fall into two main categories: those defined by their level of detail, or "fidelity," and those defined by their specific purpose. Understanding these distinctions will help you use your time and budget effectively, ensuring you get the answers you need at every step, from a rough concept to a production-ready design.

Categorizing by Fidelity Level

When we talk about "fidelity," we're really just talking about how closely a prototype resembles the final product. It’s a spectrum, ranging from a quick sketch on a napkin to a model that’s nearly indistinguishable from what will end up in your stores. Early in the process, you’ll want to stay on the low-fidelity end of the spectrum to keep things fast and flexible. As your design becomes more defined and you need to validate specific details like materials or user interaction, you’ll move toward high-fidelity models that provide a much more realistic preview of the final fixture.

Low-Fidelity Prototypes

Low-fidelity prototypes are the quick-and-dirty models you create at the very beginning of a project. Think simple sketches, cardboard mockups, or basic digital drawings. The goal here isn’t perfection; it’s speed and exploration. These prototypes are perfect for brainstorming and testing out the most basic elements of a design, like the overall size, shape, and placement of a fixture within a store layout. Because they’re so cheap and easy to make, you can explore dozens of ideas without getting too attached to any single one, allowing your team to fail fast and find the best path forward before investing significant resources.

High-Fidelity Prototypes

Once you’ve settled on a core design concept, it’s time to move into high-fidelity prototypes. These models are far more detailed and are meant to look and feel as close to the final product as possible. They are often built with production-grade materials and finishes, or created using advanced techniques like 3D printing to accurately represent the final form. A high-fidelity prototype is what you’ll use for final stakeholder approvals, customer focus groups, or to confirm that all the components fit together perfectly. This is a critical step in our design, engineering, and prototyping process, as it provides the ultimate validation before committing to large-scale manufacturing.

Categorizing by Purpose

Beyond just how they look, prototypes can also be categorized by what they do. Sometimes you don’t need a model that’s a perfect replica of the final product; you just need one that answers a specific question. Is the core idea technically feasible? Does the mechanism work as intended? Does the finish look right under store lighting? Creating prototypes with a single, clear purpose allows you to isolate variables and get targeted feedback, making the entire development process more efficient and focused. This approach ensures you’re solving the right problems at the right time.

Proof-of-Concept (PoC) Prototypes

A Proof-of-Concept prototype has one job: to determine if a core idea is even possible. It’s not meant to be pretty or comprehensive; it’s a stripped-down model designed to test a single, critical function. For example, if you’re designing a new interactive display, a PoC might just be the raw electronics on a board to prove the technology works. For a physical fixture, it could be a rough assembly to test a new weight-bearing joint or a unique locking system. The focus is entirely on technical feasibility, allowing you to quickly validate a risky or innovative concept before you build anything else around it.

Looks-Like Prototypes

Just as the name suggests, a "looks-like" prototype is all about aesthetics. Its purpose is to communicate the visual intent of the final product. This type of model will use the correct colors, materials, and finishes to show exactly how the fixture will appear in a retail setting, but it might not be functional at all. You would use a looks-like prototype to get feedback on the design's visual impact, ensure it aligns with your brand identity, and see how it complements the surrounding store environment. It’s the perfect tool for getting buy-in from marketing and design teams before moving on to functional testing.

Works-Like Prototypes

A "works-like" prototype is the functional counterpart to the "looks-like" model. Here, appearance is secondary; the entire focus is on function and mechanics. This prototype is built to test the internal workings of a design, whether it’s an adjustable shelving system, a rotating base, or an integrated lighting element. The materials used might be completely different from the final product—think raw wood, exposed hardware, and 3D-printed parts—but it will perform the same actions. This allows engineers to test, refine, and validate the fixture's durability and usability without the expense of producing a visually perfect model.

Engineering Prototypes

An engineering prototype is where everything comes together. This is a high-fidelity model that both looks like and works like the final product, and it’s designed with manufacturing in mind. It serves as the final checkpoint before you press "go" on production. This prototype is used for comprehensive user testing, final durability assessments, and to confirm the manufacturing and logistics strategy with your production partners. It’s the closest you can get to the finished item without committing to a full production run, giving you the confidence that your design is ready for a successful, large-scale rollout.

Common Rapid Prototyping Methods Explained

Once you have a digital design, it’s time to bring it into the physical world. There are several rapid prototyping methods available, and the best choice depends entirely on your project’s goals, budget, and timeline. Are you in the early stages, simply testing a concept's shape and size? Or do you need a fully functional model that looks and feels exactly like the final product you'd see in a store? Understanding the core differences between these techniques is crucial for making an informed decision that saves you time and money down the line.

Choosing the right path isn't just a technical decision; it's a strategic one. A simple 3D print might be perfect for quick, iterative feedback, while a more robust CNC-machined part might be necessary for testing the durability of a new display hook. The material, finish, strength, and speed of production all play a role. Getting this step right helps you avoid costly mistakes before committing to large-scale manufacturing. At S-CUBE, our design and engineering process is built to guide you through these choices, ensuring your fixtures are developed efficiently and effectively. Let's walk through some of the most common approaches used to create prototypes for retail displays and fixtures.

Rapid vs. Traditional Prototyping

The key difference between rapid and traditional prototyping comes down to speed, cost, and flexibility. Traditional methods often involve creating specialized tools, molds, or dies, which is a time-consuming and expensive process meant for mass production, not for creating a single test unit. If you needed to make a change, you’d often have to start from scratch, incurring significant delays and costs. Rapid prototyping, on the other hand, builds a model directly from a CAD file using techniques like 3D printing or CNC machining. This approach bypasses the need for custom tooling, allowing you to create a physical model in days instead of weeks and at a fraction of the cost.

This shift fundamentally changes the design process. Instead of treating a prototype as a final check before production, rapid prototyping encourages an iterative design cycle. You can produce a model, test it, gather feedback, and then quickly create a revised version that incorporates those changes. This allows you to identify and fix potential flaws early on, whether it’s an aesthetic detail or a functional issue that could cause problems across hundreds of stores. By testing and refining your designs this way, you can move to full-scale manufacturing with confidence, knowing you’ve already worked out the kinks and avoided a costly mistake.

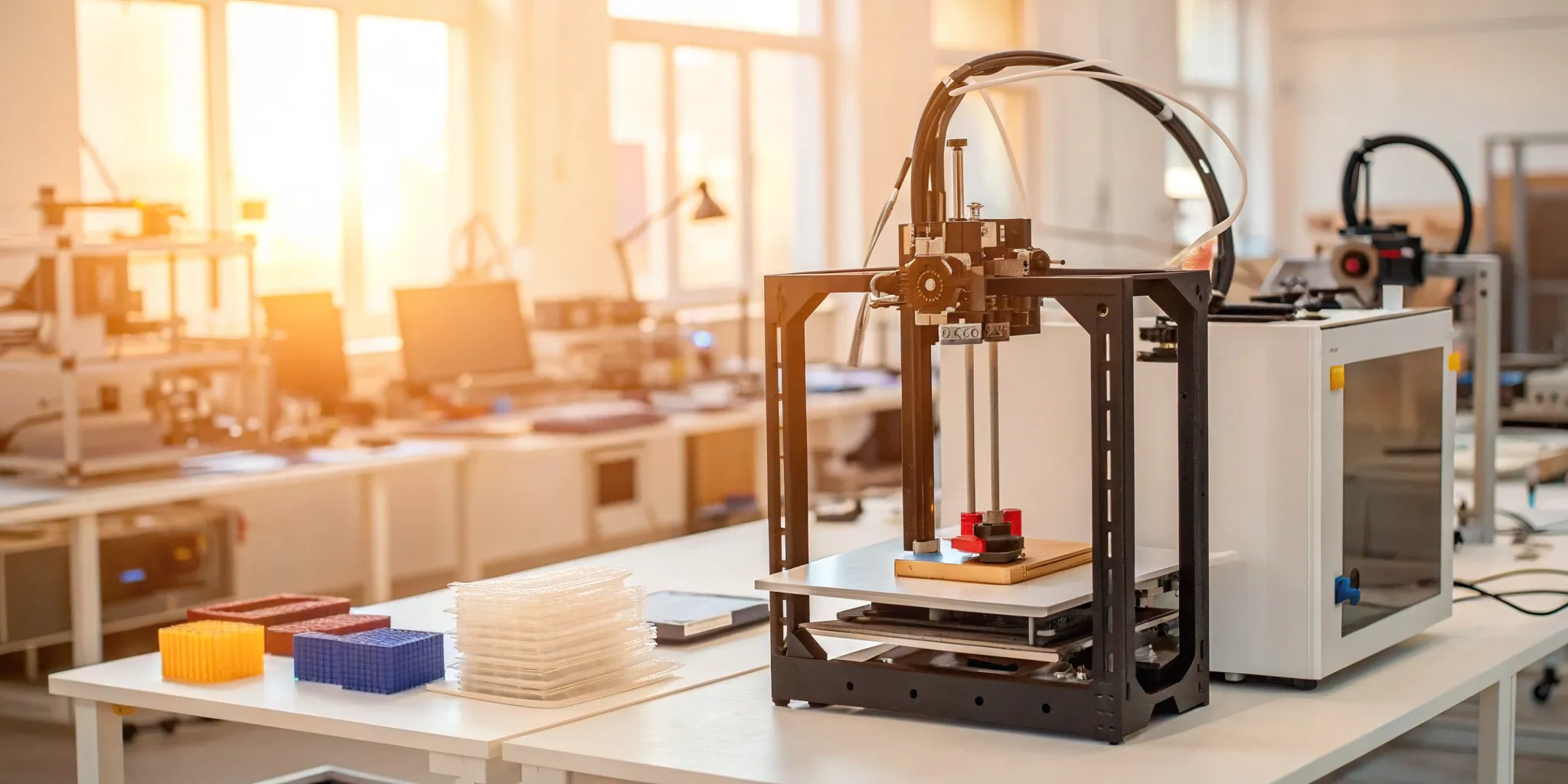

3D Printing (Additive Manufacturing)

Think of 3D printing as building something from the ground up, layer by tiny layer. This technique, also known as additive manufacturing, is incredibly versatile. Because it doesn't require special tooling, it’s perfect for creating complex or intricate shapes quickly. It’s a popular first step in the prototyping process because it allows designers to produce a physical model fast, making it easy to check for fit and form. Modern 3D printing can use a variety of materials that mimic the properties of final production plastics, giving you a realistic feel for the end product without the high initial cost.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling, or FDM, is one of the most common and accessible forms of 3D printing. It works by melting a plastic filament and extruding it layer by layer to build up an object, much like a hot glue gun drawing a three-dimensional shape. Because of its speed and low cost, FDM is an excellent choice for early-stage prototyping. It's perfect for creating simple, functional models to quickly verify the size, shape, and basic ergonomics of a new fixture component. This method allows your team to produce multiple iterations in a short amount of time, making it a highly efficient way to refine a concept before moving on to more detailed and expensive prototyping stages.

Stereolithography (SLA)

When you need a prototype with a high level of detail and a smooth, polished finish, Stereolithography (SLA) is the way to go. This technique uses an ultraviolet laser to cure liquid resin into hardened plastic, one layer at a time. The result is a model with exceptional precision, making it ideal for prototypes that require intricate features, like an embossed logo or a textured surface. SLA prototypes are often used for visual models presented to stakeholders because their high-quality finish closely resembles a final injection-molded part. This method is perfect for validating the aesthetic appeal of a design before committing to the final manufacturing process.

Selective Laser Sintering (SLS)

For prototypes that need to be strong and functional, Selective Laser Sintering (SLS) is a fantastic option. This process uses a high-powered laser to fuse powdered material, typically a durable polymer like nylon, into a solid object. A key advantage of SLS is that it doesn't require support structures during the printing process, which allows for the creation of complex internal geometries and interlocking parts. This makes it an ideal method for testing functional components of a retail display, such as hinges, brackets, or snap-fit connections that need to withstand physical stress. An SLS prototype gives you a reliable preview of the final part's strength and durability.

Direct Metal Laser Sintering (DMLS)

When your design calls for metal components, Direct Metal Laser Sintering (DMLS) offers a powerful solution. This advanced 3D printing technique uses a laser to fuse fine metal powders into solid, high-strength parts. While it's a more specialized and costly process, DMLS is invaluable for creating prototypes of custom hardware, load-bearing brackets, or security elements for high-value merchandise displays. It allows you to produce complex metal components that would be difficult or impossible to create with traditional manufacturing methods. Testing a DMLS prototype ensures that your final metal parts will have the required strength and performance for a demanding retail environment, validating the design before you invest in large-scale production.

CNC Machining (Subtractive Manufacturing)

If 3D printing is like building with blocks, CNC (Computer Numerical Control) machining is like sculpting from a solid block. This is a subtractive process, where a computer-controlled machine carefully cuts, drills, and carves away material to reveal the final design. CNC machining is known for its precision and ability to create very strong parts with smooth surface finishes from production-grade plastics and metals. When you need a prototype that can withstand physical stress testing or requires tight tolerances, CNC machining is often the best method to ensure durability and accuracy for your retail fixtures.

Injection Molding for Early-Stage Models

Injection molding is the go-to method for mass production, but it can also be used for creating high-fidelity prototypes. This process involves injecting molten material into a custom mold, resulting in strong, consistent parts with an excellent surface finish. While creating the initial mold can be more time-consuming and costly, it’s a great option when you need a small batch of prototypes that are nearly identical to the final product. It’s often used later in the development cycle, after initial designs have been validated with faster methods like 3D printing, to test with engineering-grade plastics before committing to full-scale manufacturing.

Vacuum Casting with Silicone Molds

Vacuum casting is a fantastic middle-ground for creating small batches of high-quality prototypes. The process starts by making a master model, often with 3D printing or CNC machining. A silicone mold is then created around this master. Once the mold is ready, a liquid polymer is poured in under a vacuum to remove air bubbles, ensuring a flawless copy. This method is ideal for producing parts that closely resemble the final product in texture, color, and feel. It’s perfect for creating marketing samples, conducting user testing, or validating a design before investing in expensive production tooling.

How Does the Rapid Prototyping Process Work?

Think of rapid prototyping not as a single event, but as a cycle. It’s a structured, repeatable process designed to turn a great idea into a tangible product you can hold, test, and perfect. The whole point is to move quickly, learn from physical models, and make adjustments before you commit to a full production run. This approach saves you from discovering a critical design flaw after you’ve already invested thousands in manufacturing. For retailers rolling out new fixtures across multiple locations, getting it right the first time is essential. This five-step loop is how you ensure your final design is functional, cost-effective, and ready for the sales floor. By following this framework, you can test your concepts, gather real-world feedback, and refine your vision with confidence.

Step 1: Start with a Digital Design

Every great prototype starts as a digital blueprint. Before any material is cut or printed, your idea needs to be translated into a 3D computer-aided design (CAD) file. This is the foundational step where your vision takes a specific, measurable shape. This digital model contains all the data needed to create a physical part, from its exact dimensions to its surface textures. A detailed and accurate design is crucial, as it serves as the instruction manual for the manufacturing equipment. Working with an experienced team on design and engineering ensures your digital file is optimized for production, preventing issues down the line and setting your project up for success.

Step 2: Choose Your Materials

Choosing the right material is one of the most critical decisions in the prototyping process. Your choice will influence the prototype's functionality, appearance, and cost. You don't always need to use the final production material; sometimes, a less expensive alternative can work just fine for testing the form and fit of a design. However, if you need to test for strength or durability, you’ll want a material that closely mimics the final product. For a retail display, this could mean deciding between different woods, metals, or plastics to see how they hold up and match your store's aesthetic. This decision directly impacts machining time, cost, and the quality of feedback you'll receive.

Step 3: Build the Physical Prototype

This is where your digital design comes to life. Using the CAD file as a guide, fabrication can begin. Depending on the material and complexity of your design, this might involve 3D printing, CNC machining, or another manufacturing method. The goal of this stage is speed. Rapid prototyping allows your team to get a physical model in their hands quickly, so you can start identifying any technical issues or design challenges that weren't apparent on a screen. This quick turnaround from digital to physical is what makes it possible to test and refine designs efficiently, keeping your project on schedule and within budget.

Step 4: Test, Learn, and Get Feedback

Once the prototype is built, it’s time to put it to the test. This is your first chance to see how the design works in the real world. For a retail fixture, this could involve checking its stability, seeing how easily it can be assembled, or loading it with products to assess its capacity and presentation. This hands-on evaluation helps you find and fix design problems early, avoiding expensive changes later in the production process. Gather feedback from everyone involved—engineers, designers, marketers, and even store associates who will interact with the final product. Their insights are invaluable for making meaningful improvements.

Step 5: Refine and Repeat

Prototyping is rarely a one-and-done deal. The final step is to take all the feedback from your testing and use it to refine the original digital design. This cycle of improving and testing is what makes the process so effective. You might adjust a dimension, change a material, or simplify an assembly process based on what you learned. Then, a new prototype is fabricated, and the testing process begins again. This iterative loop continues until the prototype meets all your requirements and you’re confident in the design. A dedicated project management team can help guide this process, ensuring each iteration moves you closer to a perfect final product.

How to Choose the Right Prototyping Method

With several prototyping methods available, picking the right one for your retail fixture project can feel like a major decision—because it is. The method you choose influences everything from your timeline and budget to the quality of feedback you receive. Think of it less as a technical choice and more as a strategic one. The goal is to select a process that gives you the most valuable information at the right stage of development, ensuring your final fixtures are effective, durable, and ready for a multi-store rollout.

Your choice will depend on what you need to learn. Are you testing the visual appeal of a point-of-purchase display? Or do you need to confirm the structural integrity of a new shelving unit? Answering these questions will help you find the perfect fit.

What to Consider Before You Choose

Before you can select a method, you need to define your project's core requirements. Selecting the right material is often the first and most critical step, as it sets the foundation for the entire process. An overly intricate design can lead to longer production times and higher costs, so it’s important to balance your creative vision with practical constraints. To narrow down your options, consider the purpose of your prototype. Is it a simple visual model to show stakeholders, or a functional unit for real-world testing? The level of detail, required durability, and the specific materials you plan to use for the final product will all guide your decision toward the most effective design and prototyping approach.

Balancing Speed, Cost, and Quality

Every prototyping method involves a trade-off between speed, cost, and accuracy. Understanding how to balance these three elements is key to managing your project effectively. For example, 3D printing allows teams to quickly produce multiple iterations of a design, making it ideal for early-stage validation where speed is more important than perfect accuracy. On the other hand, CNC machining might take longer and cost more, but it delivers a high-fidelity prototype that closely mimics the final product's strength and finish. The right balance depends on your goals. If you need to quickly test and refine a concept, a faster, less expensive method is best. If you're preparing for manufacturing, investing in a more accurate prototype can save you from costly errors down the line.

Matching Materials to Your Project Goals

The materials you choose for your prototype should directly support your project goals. Different industries require tailored approaches, and retail is no exception. Your fixtures need to be durable enough for a high-traffic environment while matching your brand’s aesthetic. Rapid prototyping uses various manufacturing processes like 3D printing, CNC machining, and injection molding, each compatible with different materials. If your final display will be made of metal and wood, creating a prototype from those same materials will give you the most accurate feedback on its look, feel, and durability. This alignment ensures that the insights you gain from testing are directly applicable to the final production run, reducing risks and ensuring a successful rollout.

Common Prototyping Challenges (and How to Prepare)

Rapid prototyping can feel like a superpower, letting you bring ideas to life in days instead of months. It’s an exciting phase where your vision for a new retail fixture or display starts to take shape. But like any powerful tool, it comes with its own set of challenges. The good news is that these hurdles are well-known and entirely manageable with a bit of foresight. Knowing what to expect can help you sidestep common pitfalls, keep your project on track, and ensure your investment yields the best possible results.

For national retailers planning a multi-store rollout, the stakes are even higher. A small oversight in the prototype stage doesn't just affect one fixture; it can be multiplied across hundreds of locations, leading to budget overruns, installation nightmares, and a compromised brand experience. This is why treating the prototyping phase with strategic rigor is so important. The goal isn't just to create a model—it's to pressure-test your design, validate your materials, and confirm that your fixture will perform flawlessly in the real world. By anticipating challenges related to cost, technical specs, and workflow, you shift from a reactive position to a proactive one. This approach turns potential problems into opportunities for refinement, ensuring your final fixtures are durable, effective, and perfectly aligned with your vision.

Sticking to Your Prototyping Budget

Let’s be direct: developing prototypes can be a costly endeavor, especially when you need high-fidelity models that look and feel like the final product. Budget overruns can happen when a design requires more iterations than expected or when material costs are higher than anticipated. The goal is to get valuable feedback without breaking the bank.

To prepare, start by defining a clear budget and communicating it to your design partner. A great partner will help you create a prototyping strategy that aligns with your financial plan, perhaps by starting with less expensive, low-fidelity models to validate the core concept before moving on to more detailed versions. This phased approach allows you to make critical decisions early, saving you from investing heavily in a design that isn't quite right. A clear understanding of the design, engineering, and prototyping process helps keep costs transparent and predictable.

Know the Technical Limitations

While rapid prototyping gives you incredible insight into a design’s form and function, it’s important to remember that a prototype is not the final product. The materials and methods used might not have the same precision or strength as those used in full-scale production. For example, a 3D-printed version of a display bracket will show you its exact size and shape, but it won’t be able to support the same weight as the final steel version.

The best way to handle this is to be crystal clear about the purpose of each prototype. Is it for a visual check with your marketing team? Or does it need to undergo functional stress testing? Communicating these goals to your manufacturing partner is crucial. They can guide you toward the right method and help you interpret the results, ensuring you understand what the prototype can—and can’t—tell you about your final fixture.

How to Fit Prototyping into Your Workflow

Prototyping isn’t an isolated step; it’s a critical piece of your overall product development workflow. A common challenge is ensuring a smooth handoff between your design team, the prototyping phase, and final manufacturing. Without a clear process, you can lose valuable time and information, leading to confusion and delays. The goal is to create a seamless flow where feedback from one stage directly informs the next.

To prepare, establish a clear feedback loop from the very beginning. Define who needs to review the prototype, what the approval criteria are, and how feedback will be documented and implemented. This is where working with a partner who offers strong project management and customer service becomes a huge advantage. When one team manages the entire journey from initial sketch to final rollout, you can be confident that nothing will get lost in translation.

Balancing Speed with Quality

The "rapid" in rapid prototyping is its biggest selling point, but speed should never come at the expense of quality. Rushing the process can lead you to overlook critical design flaws that become much more expensive to fix later. At the same time, spending too much time perfecting a prototype can defeat the purpose of moving quickly to get feedback and validate your ideas. The challenge is finding that sweet spot.

The key is to build a realistic timeline that accounts for thoughtful testing and iteration. A prototype gives you a huge advantage by showing you how your fixture will perform early in the cycle, so don’t cut that learning phase short. An experienced partner can help you strike the right balance, recommending the best methods for your timeline while ensuring a complete quality control process. This ensures you get the speed you need without sacrificing the quality your brand deserves.

Strategic Considerations for Prototyping

Creating a prototype is more than just a step in a checklist; it’s a strategic tool for gathering information. To get the most out of it, you need a plan. Approaching this phase with a clear strategy ensures that every model you create, from the first rough version to the final pre-production sample, provides valuable insights. It’s about asking the right questions at the right time so you can move forward with confidence, knowing your design is ready for a multi-store rollout. This thoughtful approach transforms prototyping from a simple fabrication step into a powerful process of discovery and refinement.

Set a Clear Goal for Each Prototype

Before you build anything, you need to know exactly what you’re trying to learn. A clear strategy is the key to an efficient process, so it's essential to define your goals, budget, and feedback loop before you begin. Is this first prototype just to confirm the size and shape of the fixture? Or do you need a high-fidelity model to test the durability of a specific material? Knowing the purpose of each iteration prevents you from wasting time and money on unnecessary details. For example, a simple foam model might be enough to validate a concept's footprint in a store aisle, saving the more expensive, detailed prototype for when you need to test functionality with your product line. This focused approach ensures every prototype serves a distinct purpose in your design and engineering journey.

Involve the Whole Team in the Process

A prototype isn't just for the design team; it's a communication tool for everyone involved. Bringing a tangible model to the table completely changes the conversation. It allows your team, stakeholders, and even store managers to interact with the design in a way that a 2D drawing or 3D render simply can’t match. Your marketing team can assess branding opportunities, while your operations team can spot potential installation or maintenance issues. This collaborative feedback is crucial for creating a fixture that works from every angle. A successful rollout depends on this kind of cross-departmental alignment, which is a core component of effective project management.

Test Prototypes with Real Users

A design can look perfect in the conference room, but the real test is how it performs in a retail environment. A 3D render on a screen is one thing; a physical object you can touch and interact with is another. Prototypes allow you to gather meaningful, real-world feedback from the people who will actually use the fixture, whether it’s your store associates or a customer focus group. Can associates restock it easily? Is it intuitive for shoppers to find what they need? Getting answers to these questions early on is invaluable. This type of user research helps you catch practical issues—like a shelf that’s too high or a sign holder that’s easily broken—before you commit to producing hundreds or thousands of units.

Using Prototyping in Agile Workflows

Rapid prototyping isn’t just a single step; it’s a crucial part of an iterative design cycle. It bridges the gap between a digital concept and a physical product, allowing your team to test and refine designs in a practical, agile way. Instead of following a rigid, linear path, this approach allows you to build, test, learn, and repeat in quick succession. Each iteration provides new insights that inform the next version of the design, leading to a more refined and effective final product. This flexible process ensures you can adapt to challenges and opportunities as they arise, making sure the final fixture is fully optimized before it goes into large-scale manufacturing.

How Rapid Prototyping Is Changing Retail

The retail world moves fast, and staying relevant means constantly evolving the in-store experience. Rapid prototyping is a key tool for this evolution, allowing brands to test new ideas for store layouts, displays, and customer interactions without the risk of a full-scale investment. It’s about being able to pivot quickly and confidently, ensuring your physical space keeps up with your customers' expectations. By turning concepts into tangible models, retailers can refine their vision and create environments that truly connect with shoppers.

Creating Personalized Customer Experiences

To create a memorable shopping trip, you need to understand what your customers want. Rapid prototyping lets you test different approaches to the in-store journey. Imagine creating a few versions of an interactive product display or a new checkout counter layout. You can gather real-world feedback from shoppers and staff before committing to a hundred-store rollout. This iterative process helps you fine-tune every detail, from the flow of foot traffic to the placement of key products. It allows you to develop concepts quickly and efficiently, ensuring your final design is optimized to create a welcoming and personalized experience that encourages customers to return.

Designing with AI and Customization

Technology is pushing the boundaries of what’s possible in fixture design, and AI is leading the charge. AI-powered rapid prototyping can accelerate the creative process by generating dozens of design options based on your specific needs—like budget, materials, and brand guidelines. This means you can explore more innovative and customized solutions in less time. Instead of starting from a blank slate, your design team can refine AI-generated concepts, focusing their expertise on perfecting the details. This blend of artificial intelligence and human creativity allows for smarter, faster development cycles, helping you bring a unique and highly customized vision to life across all your locations.

Prototyping with Sustainable Materials

More and more, customers are choosing to support brands that prioritize sustainability. Rapid prototyping gives you a low-risk way to incorporate eco-friendly materials into your store fixtures. Curious about a new recycled plastic or a sustainably sourced wood? Instead of placing a massive order, you can create a prototype to test the material’s durability, finish, and overall feel. This hands-on approach lets you verify that a new material meets your quality standards and brand aesthetic before you invest heavily in it. It’s a practical step toward building more sustainable retail environments without compromising on performance or design, showing your customers you’re committed to making a positive impact.

Building Better In-Store Displays and Fixtures

A great idea on paper doesn't always translate perfectly to the sales floor. Rapid prototyping bridges that gap by creating a physical model you can see, touch, and test. This process dramatically improves communication and ensures everyone from your design team to your marketing department is aligned. When you can interact with a prototype of a new point-of-purchase display, you can spot potential issues—like an awkward height or a confusing layout—long before production begins. This feedback loop cuts down on costly mistakes and speeds up your time to market. It’s a critical step in our design, engineering, and prototyping process, ensuring the final fixtures are effective, durable, and ready for a seamless rollout.

Which Industries Use Rapid Prototyping?

Rapid prototyping isn't just for one type of product or industry. Its ability to quickly turn a digital concept into a physical object has made it an essential tool across many fields. From life-saving medical devices to the phone in your pocket, prototyping helps innovators test, refine, and perfect their ideas faster than ever. Let's look at a few key sectors where this technology is making a significant impact.

Aerospace and Automotive

In the aerospace and automotive industries, there's no room for error. New parts must be rigorously tested for performance and safety, and innovation cycles are incredibly competitive. Rapid prototyping allows engineers to design and test new components quickly, moving from a digital model to a physical part in a fraction of the time it used to take. This speed allows for more iteration and refinement, leading to better, safer, and more efficient vehicles and aircraft. It’s a critical process for everything from creating lightweight brackets to testing the aerodynamics of a new body panel.

Healthcare and Medical Devices

When it comes to healthcare, precision can be a matter of life and death. Rapid prototyping plays a vital role in developing custom medical devices, surgical guides, and even anatomical models for pre-surgical planning. This technology allows for the creation of highly accurate and functional prototypes that can be tested and adjusted to meet the specific needs of a patient or procedure. By refining designs through tangible models, medical professionals can ensure better performance and ultimately contribute to improved patient outcomes. It’s a perfect example of how technology helps turn complex medical challenges into practical solutions.

Consumer Electronics

The consumer electronics market moves at lightning speed, with new products and updates launching constantly. To keep up, companies rely on rapid prototyping to accelerate their design process. Using methods like 3D printing, designers can create physical models of new devices, from phone cases to remote controls, almost instantly. This allows them to test the ergonomics, check the fit of internal components, and get a real feel for the product long before committing to expensive manufacturing tools. This flexibility is key to innovating and getting new technology into consumers' hands faster.

Retail Fixtures and Point-of-Purchase Displays

In the retail world, responding to consumer trends quickly is essential for success. Rapid prototyping is a game-changer for developing custom retail fixtures and point-of-purchase displays. It allows you to see and interact with a new display design before a full production run, ensuring it meets your exact specifications and brand standards. This process improves communication, increases efficiency, and dramatically shortens the time to market. By creating a prototype, you can test a fixture’s durability, functionality, and visual impact, making sure your final rollout creates the perfect in-store environment. Our design, engineering, and prototyping services help you do just that.

Software and UX Design

The principles of rapid prototyping aren't limited to physical products; they're just as critical in software and user experience (UX) design. Instead of a physical model, UX designers build interactive wireframes or clickable mockups. These digital prototypes let teams test the user journey, spot confusing navigation, and refine the interface before writing a single line of code. It’s the same iterative cycle of gathering hands-on feedback, just in a digital space. Much like testing a new retail display with a focus group, allowing users to interact with a concept helps developers catch usability issues early. This ensures everyone is aligned on the final vision and helps avoid costly changes down the line.

What Does Rapid Prototyping Cost?

There’s no one-size-fits-all price tag for rapid prototyping. The cost can range from a few hundred dollars for a simple model to thousands for a high-fidelity, functional prototype. Think of it less as an expense and more as an investment in getting your final product right. Spending money upfront to test and refine a design helps you avoid much larger, more expensive manufacturing mistakes down the road.

The final cost depends on a few key variables: the complexity of your design, the materials you choose, and how many versions you need to create. Understanding these factors helps you create a realistic budget that aligns with your project goals. The goal is to use prototyping to gather critical information early, ensuring your full production run goes smoothly.

What Goes Into the Cost of a Prototype?

The cost of a prototype is directly tied to the specifics of your project. One of the biggest drivers is complexity. A simple, low-fidelity model intended only to test a shape or size will naturally cost less than a detailed, functional prototype built to mimic the final product. High-fidelity designs often require more advanced tools and more expensive materials to produce.

Your choice of materials also plays a major role. Prototyping with a standard plastic will be far more affordable than using metals, custom-colored acrylics, or other specialty materials. Finally, consider the number of iterations. Most designs require a few rounds of testing and refinement. Each new version adds to the overall cost, which is why it’s so important to have clear goals for each prototype you create. An experienced partner can help you streamline this process to keep the project on track.

How to Plan Your Prototyping Budget

Planning your prototyping budget starts with clear communication and realistic expectations. Before you begin, define exactly what you need to learn from your prototype. Are you testing the fixture’s stability, its visual appeal on the sales floor, or how easily it can be assembled? Answering these questions helps you avoid paying for features you don’t need to test yet. Unclear product requirements can lead to inefficient cycles and budget overruns.

It’s also smart to plan for multiple iterations from the start. It’s rare to get a design perfect on the first try. Building two or three rounds of revisions into your budget allows for a more flexible and effective development process. By gathering more data early on, you’ll have fewer problems to solve later. Ultimately, a well-planned prototyping phase is a powerful tool that helps you accelerate innovation and launch a successful product with confidence.

Your Next Steps for Rapid Prototyping

With a solid understanding of the prototyping process, you’re ready to bring your ideas to life. But turning a digital concept into a physical object that you can hold, test, and show to stakeholders requires more than just hitting 'print.' A successful project hinges on thoughtful planning and having the right team in your corner. Before you jump in, it’s essential to map out your goals and find a partner who can guide you from the initial design to the final iteration. This approach not only saves time and money but also ensures your final product is exactly what you envisioned.

First, Outline Your Prototyping Strategy

Your prototyping strategy is your roadmap. It defines what you want to learn and how you’ll get there. Instead of creating a model just for the sake of it, a clear plan helps you focus on specific questions. Are you testing the look and feel of a new display? Verifying the fit of a specific component? Or gathering user feedback on functionality? Rapid prototyping allows your team to quickly test and refine designs, addressing technical issues that emerge during development. By defining your objectives upfront, each iteration becomes a valuable step forward, not just a shot in the dark. This clarity is the foundation of an efficient design and engineering process.

Choose the Right Partner and Tools

Your strategy is only as good as its execution, which is why selecting the right partner is critical. Look for a team that offers more than just manufacturing; you need a partner with deep industry knowledge and robust project management skills. S-CUBE has the industry know-how and manufacturing partnerships to deliver the right custom retail fixtures for you, ensuring your vision is realized correctly the first time. An experienced partner will also help you select the appropriate tools and materials for each stage. They can guide you on when a lower-fidelity model is sufficient for initial feedback versus when you need a high-precision prototype that closely mimics the final product.

Related Articles

- Display Fixture Prototyping Services: A Full Guide

- Design, Engineering & Prototyping | S-CUBE Fixtures

- A Guide to Store Fixture Prototyping Services

Frequently Asked Questions

How long does it take to get a prototype? The timeline really depends on the complexity of your fixture and the method we use. A simple 3D-printed model to check the shape and size can often be ready in just a few days. A more detailed, functional prototype made with CNC machining from production-grade materials might take a couple of weeks. The goal is always to get a useful model in your hands as quickly as possible so you can keep your project moving forward.

Do I need a finished CAD file to start the process? Not at all. Many of our clients come to us with a concept, a sketch, or just a clear idea of what they need. Our design and engineering team works with you to develop that initial idea into a professional CAD file. The prototyping process is collaborative, so you don't need to have everything perfected before you reach out. We'll help you get there.

What's the real difference between a prototype and the final fixture? Think of a prototype as a dress rehearsal. It’s designed to test specific aspects of your fixture, like its dimensions, assembly, or how it displays products. While a high-fidelity prototype can look and feel very close to the final version, it's not made with the same mass-production tooling. This means it might not have the same long-term durability or exact surface finish as the fixtures that will be rolled out to your stores.

How many prototype versions will I need? It's rare for the first version to be the final one. Most projects go through two or three rounds of prototypes. The first might be a simple model to confirm the basic design, while later versions are used to refine details and test materials. This iterative cycle is a normal and healthy part of the process, as each version gets you closer to a flawless final product that's ready for large-scale production.

Can a prototype be used in a real store for testing? Absolutely, and we often recommend it. Placing a high-fidelity prototype in a store environment is one of the best ways to gather real-world feedback. You can see how customers interact with it and get input from your store associates who will be working with it every day. This step provides invaluable insights that you simply can't get from a boardroom review, ensuring the final fixture performs perfectly where it matters most.

In-House vs. Outsourcing Your Prototyping

Deciding whether to manage prototyping in-house or to outsource it is a major strategic choice. It’s not just about who physically makes the model; it’s about how you want to manage your resources, timeline, and expertise. If your team is constantly developing and testing new fixture concepts, an in-house setup might seem appealing for its speed. However, for most retailers, whose core business isn't fixture fabrication, this can introduce unnecessary complexity and overhead. The right path depends on your project frequency, the complexity of your designs, and your long-term goals for store development.

Handling prototyping yourself can be faster for simple, frequent iterations, potentially getting a part in your hands within a day. But this approach requires a significant investment in equipment, materials, and skilled staff. For most national rollouts, partnering with an expert is the more practical and cost-effective route. Outsourcing gives you access to a full suite of technologies—from 3D printing to CNC machining—without the capital expense. It's the ideal solution when you need a few high-quality parts, are working with unusual materials, or require a level of precision that only specialized experience can provide. This ensures your focus remains on perfecting the design, not managing the fabrication process.

Keep your space ahead of the curve.

Subscribe for expert insights on fixture design, materials, and modern retail environments.