We all love acrylic for retail displays. It’s crystal clear, incredibly durable, and offers endless design possibilities. But a sheet of acrylic isn't a finished product. The real transformation happens when you partner with an expert. A custom acrylic display fabricator takes that raw potential and turns it into a stunning, brand-defining fixture. They are the specialists who precisely cut, bend, and polish the material, creating displays that do more than just hold merchandise. They build a cohesive, compelling shopping experience that makes your products shine.

Key Takeaways

- Invest in Both Style and Strength: Choose custom acrylic displays for their dual benefit. The crystal-clear quality makes your products look incredible and can increase sales, while the material's durability ensures your investment lasts, providing a consistent, high-end look across all your locations.

- Vet Your Fabricator's Entire Process: A great portfolio is just the start. For multi-store rollouts, you need a partner with proven project management and communication skills to handle everything from design to logistics, ensuring your project is delivered on time and on budget.

- Approve the Prototype Before Full Production: The prototype is your most important checkpoint. Use this stage to make final adjustments to the design and test its functionality. Getting it right here ensures the final product meets your exact specifications and prevents costly issues down the line.

What Is a Custom Acrylic Display Fabricator?

When you need a display that’s durable, crystal-clear, and perfectly matched to your products and brand, you turn to a custom acrylic display fabricator. These are the specialists who work with acrylic plastic—often known by brand names like Plexiglas or Lucite—to create fixtures tailored to your exact specifications. Unlike off-the-shelf solutions, a fabricator partners with you to design and produce displays that fit your space, highlight your merchandise, and support your sales goals.

For national retailers and growing chains, working with an experienced fabricator is key. They have the expertise and equipment to handle everything from a single prototype to a large-scale rollout across hundreds of stores. They understand the demands of the retail environment and can deliver high-quality, consistent products that strengthen your brand presentation everywhere. A great fabricator acts as an extension of your team, helping you create a successful and visually appealing retail environment.

Exploring Their Services and Capabilities

A custom acrylic display fabricator is much more than just a supplier; they are a creative and technical partner. Their primary job is to transform raw acrylic sheets into polished, functional displays. This involves a range of specialized services that allow for nearly endless customization. They can cut acrylic to any size or shape with incredible precision using techniques like laser cutting and CNC routing, which is perfect for creating intricate logos or unique fixture designs.

Beyond cutting, they offer services like thermoforming to bend and mold acrylic into curved shapes, and UV printing to apply full-color graphics and branding directly onto the surface. This design and engineering expertise means you can create everything from simple sign holders to complex, multi-part displays. They work with you to ensure the final product is not only beautiful but also structurally sound and built to last in a busy retail setting.

Inspiration: Popular Custom Acrylic Products

The versatility of acrylic means it can be used to create a huge variety of products that serve different functions in a retail store. You’ve likely seen many examples without even realizing it. Common products include countertop display cases for jewelry or electronics, risers that add height and dimension to your visual merchandising, and protective cases for valuable collectibles or artifacts. These items are designed to put the focus on your products while keeping them safe.

Other popular examples include custom signage, branded blocks that add a sophisticated touch to a display, and secure ballot boxes for contests or customer feedback. Fabricators can also produce trays for organizing small items, literature holders for brochures, and even entire point-of-purchase (POP) displays. Looking at a fabricator’s portfolio of past work is a great way to see the range of possibilities and get inspiration for your own project.

Common Designs and Customization Options

One of the biggest advantages of working with a fabricator is that your displays are made to order, built to your exact specifications. This goes far beyond just choosing a size. You can dictate the thickness of the acrylic for added durability, incorporate secure locking mechanisms for high-value items, or add adjustable shelving to accommodate different products. Branding is another key area for customization. Your logo can be laser-etched for a subtle, high-end look, or full-color graphics can be printed directly onto the display to catch the customer’s eye. A skilled fabricator provides the design and engineering support to turn your vision into a functional, beautiful fixture that strengthens your brand identity across all your locations.

Exploring Base Colors and Finishes

While crystal-clear acrylic is a classic for a reason—it keeps the focus squarely on your products—color and finish play a huge role in defining your brand's aesthetic. Solid black or white acrylic can create a bold, modern contrast that makes merchandise stand out, especially in tech or beauty retail. For a pop of personality, many fabricators offer bases and accents in a wide spectrum of colors, including vibrant reds, blues, and greens. You can also move beyond the standard glossy finish. Frosted or matte acrylic offers a softer, more diffused look that minimizes glare and fingerprints, while specialty finishes like faux wood can add a touch of warmth and sophistication. These choices help create a cohesive and memorable in-store experience, and you can see our work to get ideas for your own displays.

Why Your Business Needs Custom Acrylic Displays

In a busy retail space, your products need to do more than just sit on a shelf—they need to capture a customer's attention. Custom acrylic displays are a fantastic tool for making that happen. They offer a clean, modern way to present your merchandise, creating an inviting experience that draws shoppers in. Beyond just looking good, these displays are a practical choice for any growing business. They’re built to last, can be tailored to fit your brand perfectly, and ultimately provide a strong return on your investment by helping you sell more products. Let's look at exactly why custom acrylic is a smart move for your stores.

Make Your Products Stand Out

The primary job of any display is to make your products look their best, and acrylic excels at this. Its crystal-clear quality allows your merchandise to be the star of the show without any visual clutter. This clean presentation helps customers get a better look at what you’re selling and can make your entire setup feel more modern and high-end. Well-designed point-of-purchase displays made from acrylic can stop shoppers in their tracks, pulling them toward a specific item or promotion. By using attractive designs, you can guide the customer’s eye exactly where you want it, building your brand’s reputation for quality and style right at the point of sale.

Choose Displays That Are Built to Last

When you’re outfitting multiple store locations, you need fixtures that can handle the demands of a busy retail environment and the logistics of getting them there. Acrylic is a great choice because it’s incredibly durable. Unlike glass, it’s shatter-resistant, which means less worry about breakage during shipping or from accidental bumps in-store. It’s also lightweight, which can help reduce shipping costs for large rollouts. Because acrylic retains its clarity over time without yellowing, you can trust that your displays will continue to showcase products cleanly and professionally for years. This long-lasting quality ensures a consistent look across all your locations.

Reflect Your Brand with a Unique Design

Your store fixtures are a direct reflection of your brand, and custom acrylic gives you the freedom to create a look that is completely your own. The customizability of acrylic means you aren't limited to standard shapes or sizes. You can work with a fabricator to design displays that fit your products perfectly and align with your brand’s aesthetic, whether that includes unique dimensions, curves, or colors. This level of personalization is essential for creating a cohesive and memorable shopping experience. With a partner who specializes in design and prototyping, you can bring your specific vision to life and ensure your brand stands out from the competition.

Get a Better Return on Your Investment

Investing in custom fixtures should directly benefit your bottom line, and acrylic displays deliver a solid return. First, their ability to make products pop and grab attention can lead directly to more sales. When merchandise is presented clearly and attractively, customers are more likely to make a purchase. Second, their durability means you won’t have to spend money on frequent replacements, lowering your long-term operational costs. This combination of increased sales and reduced expenses makes custom acrylic a financially sound decision. It’s an investment in your brand’s presentation that pays for itself over time.

Understanding the Properties of Acrylic

To make smart decisions about your store fixtures, it helps to know a bit about the material itself. Acrylic is more than just a clear plastic; its specific properties are what make it such a reliable choice for retail. Understanding its strengths and capabilities will give you confidence in your investment and help you communicate your vision to your fabricator. We'll cover the key characteristics that make acrylic a go-to material for creating displays that are both beautiful and built to perform in a demanding retail environment.

Material Specifications

At its core, acrylic is a type of plastic known for its exceptional clarity and strength, often recognized by brand names like Plexiglas or Lucite. This isn't your average plastic; it's engineered to be both visually stunning and incredibly resilient. Its glass-like transparency ensures that your products are the main attraction, without any distortion or yellowing over time. This high-end look, combined with its inherent durability, means it can easily handle the daily interactions of a busy store, from customer contact to routine cleaning, ensuring your displays maintain their premium appearance across all your locations.

Temperature Range and Water Resistance

One of acrylic's most practical advantages is its ability to perform well under various conditions. It can withstand a wide temperature range, typically from -30 to 190 degrees Fahrenheit, so you don't have to worry about displays warping or becoming brittle near a sunny window or under hot display lighting. Furthermore, acrylic is resistant to water, which makes cleaning simple and protects your investment from accidental spills. This resilience ensures your fixtures will maintain their structural integrity and pristine look, no matter the specific environment of your retail space.

Available Sizes and Thicknesses

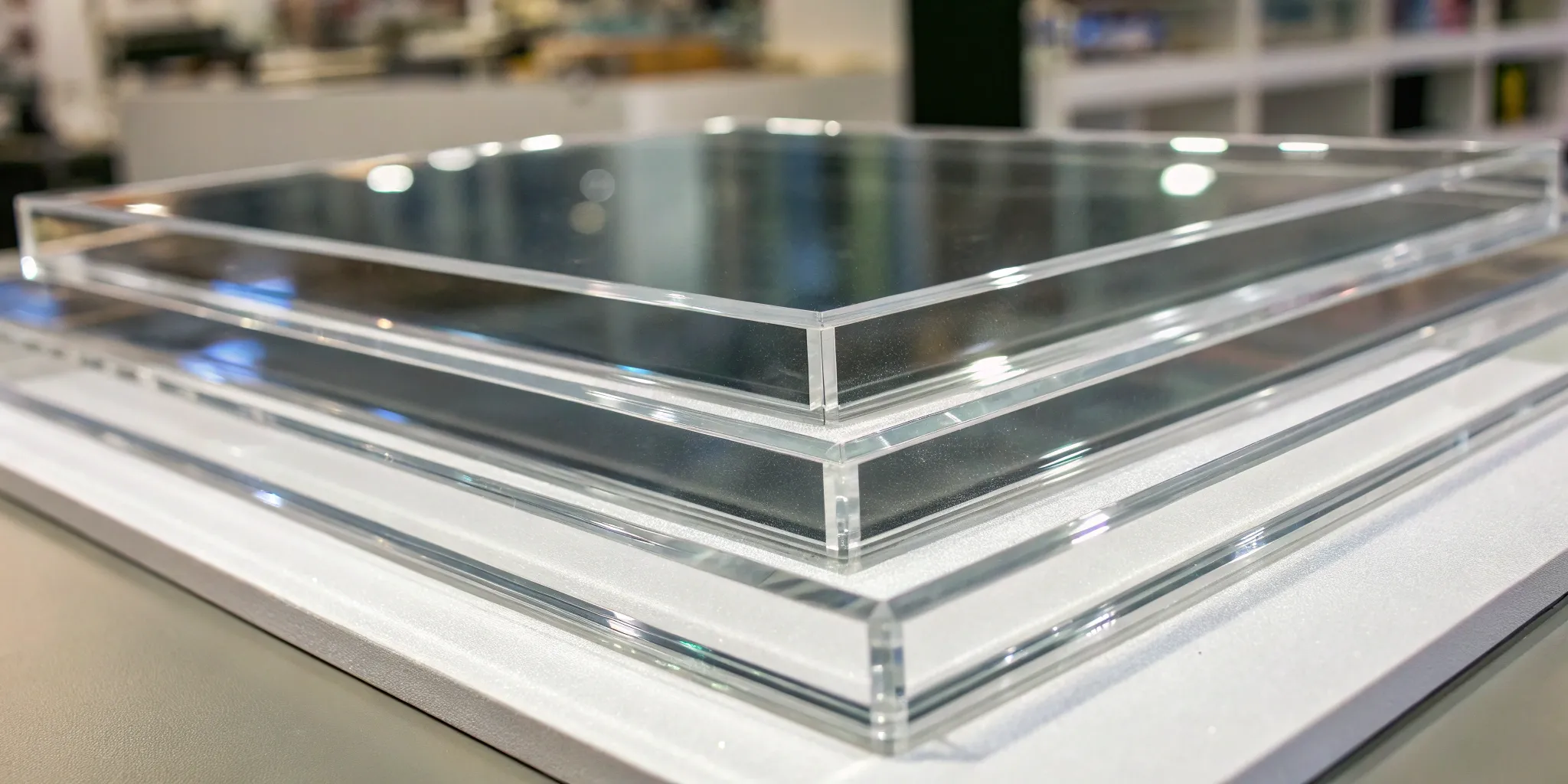

The design possibilities with acrylic are vast, thanks in large part to the wide range of sizes and thicknesses available. Acrylic sheets can be sourced in thicknesses ranging from a slim 1/16 inch up to a substantial 3 inches. This flexibility is key for custom fabrication, as it allows designers and engineers to select the perfect thickness for each component of a display. For example, a thinner sheet might be ideal for a simple sign holder, while a thicker, more robust sheet would be necessary to provide structural support for a large, weight-bearing countertop case.

Standard Sheet Sizes and Thickness Variations

While acrylic is commonly produced in standard 4-foot by 8-foot sheets, a skilled fabricator isn't limited to these dimensions. These large sheets can be precisely cut down to any size needed, but it's also possible to source custom-sized sheets for unique or large-scale projects. This adaptability is crucial for retailers who need to maximize every inch of their merchandising space with displays that are tailored to specific products or store layouts. Working with a partner who understands how to leverage these material options is essential for creating a truly custom fixture program that feels cohesive and perfectly suited to your brand.

How to Choose the Right Fabricator for Your Project

Finding the right partner to create your custom acrylic displays is a big decision, especially when you’re coordinating a rollout across dozens or even hundreds of locations. This isn't just about buying a product; it's about investing in a solution that will represent your brand and engage your customers in every single store. The right fabricator does more than just make things; they become an extension of your team, a strategic partner dedicated to ensuring your vision comes to life on time and on budget, consistently and at scale. A poor choice can lead to missed deadlines, budget overruns, and inconsistent quality that ultimately undermines your brand image and affects your sales. To make sure you’re partnering with the best, you’ll want to look closely at four key areas: their experience, design capabilities, technical skills, and approach to customer service. Taking the time to vet these areas will help you find a reliable fabricator who can deliver the quality and consistency your brand deserves.

Check Their Portfolio and Track Record

Before you commit, take a good look at a fabricator’s track record. A company with deep experience will have a portfolio that speaks for itself. Ask to see examples of their previous projects, paying close attention to work they’ve done for businesses similar to yours. Seeing successful displays they’ve created for other national retailers or multi-location brands is a great indicator of their ability to handle large-scale projects. A strong portfolio shows you they not only have the skills but also understand the unique challenges of a retail environment. Reviewing our work can give you a clear idea of the quality and scope you should expect from a seasoned fabricator.

Can They Bring Your Vision to Life?

Your acrylic displays need to reflect your brand’s unique identity, so a fabricator’s design and customization skills are key. Can they take your concept and turn it into a functional, beautiful fixture? Look for a partner who offers comprehensive design and engineering services, from initial sketches to finished prototypes. The best fabricators will work with you to refine your ideas and can handle complex specifications, whether it’s a unique shape, a specific color match, or custom engraving. This collaborative approach ensures the final product is exactly what you envisioned and perfectly tailored to your needs.

Confirm Their Technical Skills and Material Quality

The look and longevity of your displays come down to two things: the quality of the materials and the technology used to shape them. Don’t hesitate to ask a potential fabricator about the grade of acrylic they use and their processes. A top-tier partner will use high-quality materials and advanced fabrication techniques like CNC machining, laser cutting, and thermoforming to create precise, polished, and durable fixtures. Their technical expertise is what guarantees your displays will not only look great on day one but will also stand up to the demands of a busy retail setting for years to come.

Evaluate Their Communication and Project Timelines

Great displays are only one part of the equation; a smooth process is just as important. Strong communication and reliable project management are non-negotiable, especially for multi-store rollouts. Ask about their process for handling projects, from kickoff to delivery. A dedicated project management team can make all the difference, providing clear updates and ensuring deadlines are met. You need a partner who understands the importance of your timeline and can efficiently coordinate production and logistics to get your fixtures to every location without a hitch. This level of service is what separates a simple supplier from a true strategic partner.

What to Expect During the Fabrication Process

Once you’ve chosen a fabricator, the real work begins: turning your vision into a tangible display. Understanding the fabrication process helps you set realistic timelines, provide the right feedback, and feel confident in your investment. A great partner will guide you through every stage, making sure the final product aligns perfectly with your goals. The journey from a simple idea to a fully installed fixture involves several key steps, each one building on the last to ensure a successful rollout for all your locations.

This process is a collaboration. Your input during the design and prototyping phases is essential for getting the details right before your project moves into full production. A well-managed fabrication process ensures there are no surprises, and the displays that arrive at your stores are exactly what you envisioned. At S-CUBE, we’ve refined our project management approach to make this journey as smooth and transparent as possible. We believe clear communication and a structured workflow are the foundation for delivering high-quality fixtures on time, every time, keeping you informed from start to finish so you can focus on your business.

The Process: From Your Idea to the Final Product

Bringing a custom acrylic display to life follows a clear path. It starts with your initial concept and ends with the finished product in your retail space. First, you’ll work closely with the fabricator’s team on design and engineering. This is where you share your ideas, brand guidelines, and functional needs. The team then translates this into technical drawings and 3D renderings. Once the design is refined, they’ll create a prototype. This sample gives you a chance to see and touch the display, test its durability, and make any final adjustments before committing to a full production run. After you approve the prototype, manufacturing begins, followed by careful logistics and distribution to get your new displays to all your locations.

Starting with a Simple Sketch

You don’t need a professional CAD drawing to kick off your project. In fact, the process often begins with a simple sketch. A reliable fabricator has a skilled design and engineering team ready to translate your vision into a production-ready design. What’s most important at this stage is communicating your core needs. Your sketch should include basic details like the approximate dimensions, the thickness of the acrylic you have in mind, any specific colors, and the quantity you’ll need for your rollout. This initial concept serves as the perfect starting point for a collaborative conversation, allowing the experts to refine the technical details and ensure the final fixture is both functional and true to your brand.

Understanding Return Policies for Custom Work

It’s essential to know that custom-fabricated orders are almost always final sale. Because these displays are created to your unique specifications, they can’t be restocked or resold to another business. This industry-standard policy makes the prototype approval stage the single most important checkpoint in the entire process. This is your opportunity to physically interact with the display, test its functionality with your products, and request any final changes. A trustworthy partner will emphasize this step, ensuring you are completely satisfied with the prototype before moving into full production. This careful approach protects your investment and guarantees the final fixtures that arrive at your stores are exactly what you approved.

A Look at Modern Fabrication Techniques

The actual creation of your acrylic displays involves some impressive technology. Fabricators use advanced methods to achieve precise and high-quality results. Techniques like CNC machining and laser cutting use computer-controlled tools to cut acrylic sheets into exact shapes with clean, polished edges. For displays with curves or unique forms, fabricators use thermoforming, a process that involves heating the acrylic until it’s pliable and then molding it into the desired shape. To add branding and graphics, many use UV printing, which applies ink directly onto the acrylic surface for a durable, vibrant finish. These manufacturing capabilities are what allow for truly custom and creative designs that make your products stand out.

Typical Production Timelines

Understanding the production timeline is crucial for planning a successful rollout. While a simple, one-off custom piece might be ready in a couple of weeks, a large-scale order for a national chain is a different story. The timeline for a multi-store project depends on the complexity of the design, the number of units, and the prototyping phase. A reliable fabricator will provide a detailed schedule that accounts for design approval, material sourcing, manufacturing, and shipping. For retailers, hitting deadlines for new store openings or seasonal campaigns is non-negotiable. This is where a partner with strong project management shines, as they can coordinate every step to ensure your displays are ready exactly when you need them, avoiding costly delays.

Shipping, Delivery, and Pickup Logistics

Getting your finished displays to all your locations safely and on time is the final, critical step. For national retailers, this means you need a partner with robust logistical capabilities, not just a local shop that offers curbside pickup. A fabricator experienced with large rollouts will have a system for packaging fixtures to prevent damage during transit and will manage the entire distribution process. They can coordinate freight shipments to hundreds of individual stores across the country, ensuring each location receives the correct items. This level of logistics and distribution expertise is essential for a smooth, hassle-free launch, allowing your store teams to focus on setup and sales rather than chasing down shipments.

Popular Uses for Custom Acrylic Displays

Acrylic is one of the most versatile materials you can work with, which is why you see it everywhere from high-end boutiques to bustling trade show floors. Its clean look and durability make it a go-to choice for a wide range of applications. Whether you want to make your products pop, protect valuable items, or create cohesive branding across multiple locations, custom acrylic displays offer a practical and stylish solution. Let’s look at some of the most popular ways businesses use them.

Making an Impact in Retail and at Trade Shows

In a competitive retail setting, your displays need to do more than just hold products—they need to stop shoppers in their tracks. Custom acrylic fixtures are perfect for creating visually stunning setups that draw customers in and encourage them to interact with your merchandise. Because acrylic is so clear, it puts the full focus on your products, making colors look brighter and details sharper. This enhanced product visualization helps create a modern, premium feel in your store, which builds your brand's reputation. From countertop displays for new cosmetic lines to freestanding fixtures for accessories, the right acrylic display can make a real difference in your sales and customer experience. See examples of how we help create successful retail environments in our work gallery.

Ideal for Museums, Galleries, and Hospitality

Beyond the retail floor, acrylic is a trusted material for protecting and showcasing valuable items. Museums and galleries use acrylic cases, stands, and mounts to display artifacts and artwork elegantly while keeping them safe from dust and handling. The optical clarity of acrylic ensures that viewers get an unobstructed view, almost as if there’s nothing there at all. In the hospitality world, hotels use custom acrylic fixtures for everything from sophisticated menu holders and room number signs to beautiful displays for amenities in the lobby or spa. These applications show just how well acrylic can be adapted to create a high-end, protective, and beautiful presentation for any special item you want to feature.

Custom Signage and Branded Fixtures

Consistent branding is key, especially when you’re managing multiple locations. Acrylic is an excellent choice for custom signage and branded fixtures because it’s lightweight, durable, and easy to maintain. You can use it to create everything from sleek, dimensional logos behind your cash wrap to branded shelf talkers and informational signs throughout your store. Because of its high transparency and smooth surface, graphics and text look crisp and professional. This versatility allows you to design a cohesive look that complements your store’s aesthetic and reinforces your brand identity at every turn. Our design and engineering services can help you develop the perfect branded fixtures for a national rollout.

How to Care for Your Acrylic Displays

You’ve invested in beautiful, custom acrylic displays to make your products shine. Now, let’s make sure they stay that way. Proper care is simple, but it’s key to keeping your fixtures looking crystal clear for years. Unlike glass, acrylic requires a slightly different approach to cleaning and handling. With just a few easy habits, you can protect your displays from scratches, clouding, and damage, ensuring they continue to represent your brand flawlessly.

Simple Tips to Make Your Displays Last

The number one rule for acrylic care is to be gentle. While durable, acrylic can scratch more easily than glass, so it’s best to avoid abrasive cloths, paper towels, or harsh scrubbing. The easiest way to keep your displays looking brand new is to dust them regularly. A quick wipe-down with a soft, clean microfiber cloth is usually all it takes to remove surface dust and prevent buildup. This simple step helps you maximize your visual merchandising potential by ensuring your products are always seen through a crystal-clear, pristine surface. Think of it as simple preventative maintenance for a critical store asset.

The Right Way to Clean and Maintain Acrylic

For smudges or spills that require more than a dry cloth, you’ll want to skip the Windex. Standard glass cleaners that contain ammonia or other harsh chemicals can cause permanent clouding or even tiny cracks in the acrylic over time. The benefits of acrylic displays are numerous, but preserving their clarity is essential. Instead, opt for a simple solution of mild soap and lukewarm water applied with a soft cleaning cloth. You can also find cleaning solutions made specifically for acrylic. Gently wipe the surface, rinse with clean water, and blot dry with another soft cloth to prevent water spots. This method will safely clean your fixtures without risking damage.

How to Budget for Custom Acrylic Displays

Creating a budget for custom fixtures can feel tricky, but it’s all about understanding the moving parts. Acrylic is a fantastic choice for its clarity and durability, making it a go-to for everything from retail displays to corporate signage. When you go custom, you’re paying for a solution tailored to your exact needs, so the final price tag will reflect the unique specifications of your project. The key is to know which factors have the biggest impact on cost so you can make informed decisions that align with your financial goals without compromising on the quality your brand deserves.

What Determines the Final Price?

The final cost of your custom acrylic displays depends on a few key variables. The first is the material itself—specifically, the thickness and grade of the acrylic. Thicker sheets cost more but offer greater strength for larger or weight-bearing displays. The complexity of your design also plays a major role. A simple bent stand will be more affordable than an intricate, multi-part display with polished edges and engraved logos.

Finally, consider volume and finishing. As with most manufacturing, ordering a larger quantity of displays typically lowers the per-unit cost. Special features like screen printing, vinyl graphics, or added hardware will also influence the final price. An experienced fabricator can walk you through these options and explain how each choice affects your bottom line.

Typical Starting Price Points

While it’s helpful to have a starting point, the price of a custom acrylic display can vary significantly based on your project's specifics. For a very simple, small item like a basic display case, you might see prices starting around $45. However, this is just a baseline. The true final cost is shaped by the factors we just discussed: material thickness, design complexity, and any special finishes. A simple riser will naturally cost less than a large, branded point-of-purchase display with multiple components. The best approach is to discuss your needs with a fabricator who can provide a detailed quote. Remember that for larger rollouts, volume discounts often apply, which can lower the per-unit price and make a custom solution more cost-effective than you might think.

How to Balance Your Budget with Quality

Getting the most for your money doesn’t mean settling for less. It’s about being strategic. You can create stunning, effective displays on a budget by focusing on smart design. For instance, acrylic’s natural transparency and lightweight properties already give you a head start, creating a high-end look and potentially reducing shipping costs. The freedom to customize the display allows you to focus your budget on the features that matter most for your products.

Working with a knowledgeable partner is crucial here. A team with deep design and engineering expertise can suggest minor adjustments that lower costs without sacrificing visual impact or durability. They can help you choose the right material thickness for your needs and find production efficiencies that make your budget work harder.

Why a Quality Display Is a Smart Investment

When you invest in high-quality acrylic displays, you’re doing more than just buying a fixture; you’re investing in your brand’s success. These displays are built to last, which means you won’t have to worry about frequent replacements. Their durability and timeless appeal provide lasting value that far outweighs the initial cost. Clear, well-crafted displays make your products look their best, and that improved visibility can directly lead to increased sales.

Think of your displays as a silent salesperson working for you around the clock. They create a polished, professional atmosphere that builds customer trust and reinforces your brand’s commitment to quality. By partnering with a fabricator who understands how to create successful retail environments, you ensure your investment pays dividends for years to come.

Sustainability and Acrylic Displays

The Role of Recycled Materials

Sustainability is a huge conversation in retail right now, and it’s influencing everything from packaging to store design. When it comes to fixtures, custom acrylic displays are part of that conversation too. One of the most exciting developments is the use of recycled materials. For example, some fabricators now work with certified recycled acrylic, which offers a way to reduce waste and support a more sustainable manufacturing process. This isn't a compromise on quality; these materials still provide the same clarity and durability you expect from virgin acrylic. Companies that prioritize recycling can make a significant environmental impact, with some recycling hundreds of tons of acrylic each year and preventing thousands of tons of CO2 emissions. By choosing displays made from recycled content, you can lower your carbon footprint, enhance your brand’s reputation, and connect with environmentally conscious shoppers.

A Rundown of Top Custom Acrylic Display Fabricators

Finding the right partner to bring your vision for acrylic displays to life is a big decision. The quality of their work directly impacts how customers perceive your brand and products. To help you get started, I’ve put together a list of some of the top custom acrylic display fabricators out there. Each company has its own strengths, whether it’s handling massive rollouts or creating highly specialized designs. This will give you a solid starting point for finding the perfect fit for your project.

S-CUBE Retail Fixtures

With over 30 years in the business, we at S-CUBE have a deep understanding of what it takes to create successful retail environments. We specialize in producing custom retail fixtures that not only look great but also perform flawlessly. Our process is comprehensive, covering everything from initial design and engineering to manufacturing and logistics. We work closely with you to ensure your acrylic displays perfectly capture your brand’s identity and enhance the overall shopping experience. For national retailers and regional chains, our expertise in managing large-scale programs means you get consistent quality and on-time delivery for every single location.

Acrylic Design

Acrylic Design has built a reputation for its innovative and high-quality approach to acrylic fabrication. They are known for creating displays that are both durable and visually striking, making them a versatile partner for a wide range of retail needs. Their team focuses on using advanced fabrication techniques to produce everything from simple sign holders to complex, multi-part product displays. If you’re looking for a fabricator that combines creative design with a commitment to aesthetic appeal, Acrylic Design offers a strong portfolio of solutions designed to make products shine and draw customers in.

Displays2go

If you’re looking for variety and a massive selection, Displays2go is a major name in the display market. They offer an incredibly broad catalog that includes both ready-made stock items and fully custom acrylic solutions. This flexibility is great for businesses that may need a mix of standard displays and unique, branded fixtures. Their user-friendly website makes it easy to browse thousands of options, which can be a fantastic source of inspiration. For retailers who value convenience and a wide array of choices, Displays2go provides a one-stop-shop experience for finding the right display solutions quickly.

Shoppopdisplays

Specializing in point-of-purchase (POP) displays, Shoppopdisplays focuses on creating fixtures that stop customers in their tracks. Their expertise lies in designing eye-catching acrylic displays that make products stand out in a crowded retail space. They work with clients to develop custom solutions that are not only visually appealing but also strategically designed to drive sales right at the checkout counter or on the sales floor. Known for their commitment to quality and attentive customer service, Shoppopdisplays is a solid choice for brands looking to make a direct impact on purchasing decisions through creative and effective POP fixtures.

Polyfab Plastics & Design

Polyfab Plastics & Design is recognized for its technical expertise and precision in the world of acrylic fabrication. They are true specialists in the material, offering custom display solutions that are meticulously crafted to meet exact client specifications. Their focus on quality and precision ensures that every piece they produce is not only beautiful but also structurally sound and perfectly functional for its intended retail environment. For businesses that require a high degree of technical skill and a partner who understands the nuances of working with acrylic, Polyfab is a go-to fabricator for tailored, high-performance displays.

Why Choose S-CUBE for Your Custom Acrylic Displays?

When you’re investing in custom displays for dozens or even hundreds of locations, you need more than just a fabricator. You need a partner who can manage the entire project from start to finish, ensuring consistency and quality across the board. At S-CUBE, we combine deep industry knowledge with a seamless process to bring your vision to life, on time and on budget. We understand that a great display does more than just hold products—it creates an experience that draws customers in.

Our Seamless Process and Deep Expertise

Managing a large-scale fixture rollout can be complex, but our process makes it simple. We handle every step in-house, from initial design and engineering to manufacturing, logistics, and installation. This all-in-one approach means you have a single point of contact and a dedicated team overseeing your project. With over 30 years of experience, we know what we do works. We’ve helped national retailers create visually stunning acrylic displays that not only look great but also encourage customers to engage with products, ultimately driving sales. Our expertise spans retail, hospitality, and beyond, giving us the insight to build fixtures that perform in any environment.

Our Commitment to Quality and Your Success

Your brand deserves fixtures that reflect its quality, and that starts with the materials we use. We choose acrylic for its superior clarity, light weight, and impressive durability, ensuring your displays can withstand the demands of a busy retail setting. But our commitment goes beyond the physical product. We believe true success comes from a partnership. Our team works closely with you to customize every detail, from the type of acrylic to the exact shape and size that fits your brand aesthetic. With a rigorous quality control process at every stage, we make sure your final displays are flawless and built to last.

Related Articles

- Custom Retail Display Cases: The Ultimate Guide

- Custom Point-of-Purchase Displays: A Retailer's Guide

- The Benefits of Custom Displays In Retail

- Custom POP Displays: A Comprehensive Guide

- Custom Fabrication for Retail: A Complete Guide

Frequently Asked Questions

What’s the real difference between working with a fabricator and just buying stock displays online? Think of it as the difference between buying a suit off the rack and having one custom-tailored. Stock displays are a one-size-fits-all solution, which can work in a pinch. But a custom fabricator acts as your partner, designing and engineering displays specifically for your products, your brand, and your store environment. This collaboration ensures your fixtures not only fit perfectly but also solve unique merchandising challenges and create a cohesive look across all your locations.

How long does it typically take to get custom acrylic displays made? The timeline for a custom project depends on a few things, like the complexity of the design and the number of displays you need. The process generally moves through three key phases: design and prototyping, full production, and logistics. A simple design might move quickly, while a more intricate fixture for a large-scale rollout will require more time for refinement and manufacturing. A good fabricator will provide a clear project timeline upfront so you know exactly what to expect.

Are acrylic displays always clear, or can they be made in different colors? While the crystal-clear look is one of acrylic's most popular features, it’s incredibly versatile. Acrylic can be produced in a huge spectrum of transparent tints, opaque colors, and even frosted or mirrored finishes. This gives you the creative freedom to perfectly match your displays to your brand’s color palette and create a look that is completely unique to your stores.

Is acrylic strong enough to hold heavy or valuable products? Absolutely. While it’s lightweight, acrylic is surprisingly strong and shatter-resistant, making it a very durable choice for a busy retail floor. An experienced fabricator will work with you to understand what products the display will hold and then engineer it using the appropriate thickness and structural design to ensure it can safely support the weight. For valuable items, they can also incorporate security features into the design.

What information should I have ready before I contact a fabricator for a quote? Coming prepared helps the process move smoothly. It’s helpful to have a general idea of the display’s purpose, the dimensions of the products it will hold, and the quantity you’ll need for your stores. If you have any brand guidelines, like specific colors or logos you want to include, have those handy as well. Even if you only have a rough concept, a good design team can work with that to start building your perfect display.

Keep your space ahead of the curve.

Subscribe for expert insights on fixture design, materials, and modern retail environments.